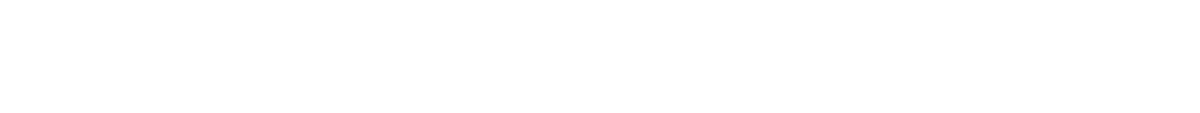

A2L Refrigerant Charging System

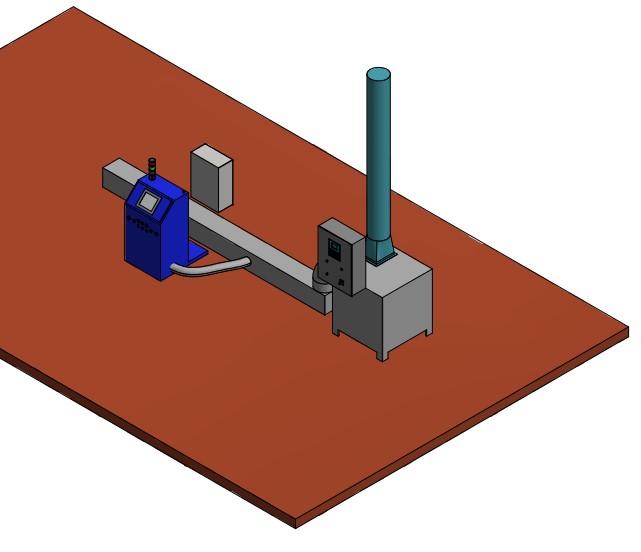

Airserco offers custom built A2L refrigerant charging areas that include a number of safety features to make your charging area comply with your facility’s specific location regulations.

Available A2L Charging Area Safety Components

- Charging Machines that are built for A1, A2L, and A3 Refrigerants. With optional integration of Pressure Testing, Tracer Gas Injection, Evacuation, Rise/Decay Testing, and PAG oil Injection.

- Medusa Safety Controllers - To monitor the Charging Environment and maintain a safe environment.

- Infrared Refrigerant Leak Sensors - To monitor the area for possible refrigerant leaks.

- Refrigerant Transfer Pumps

- Refrigerant Tank Change Systems

- Ventilation Extraction Systems

- Tank Isolation Valves

- Etc.

Only logged in customers who have purchased this product may leave a review.

Microprocessor or smart OS (optional) controlled

Charging speed: up to 25 g/s for HC/HFO refrigerants and up

Charging capacity: according to local limitations

High charging accuracy

Built-in vacuum pump (20,5 m³/h)

Available with integrated Refrigerant transfer Pump

Interactive Color Touchscreen

Data Collection Application over TCP/IP protocol

Up to 1000 programmable work cycles Microprocessor-controlled

Built-in according to the European Machinery Directive, Safety standards for Potential Dangerous Areas

Works with A1, A2L, and A3 refrigerants including:

Class A1 – Non Flammable

- R134A

- R410A

- R-407C

- R-22

Class A2L – Mildly Flammable

- R454B

- R1234yf

- R1234ze

- R32

Class A3 – Highly Flammable

- R290 (propane)

- R600 (butane)

- R-600A (isobutane)

Have questions about this product?

Continue Browsing Our Products

Automatic Charging & Evacuation

Airserco has pioneered the development of refrigerant processing equipment that is accurate, dependable, and cost-effective. Airserco equipment is compatible with virtually all refrigerants of today and tomorrow. With more than 80 years of history, Airserco offers a wide range of equipment to meet your needs.

Vacuum Gauges

Airserco Vacuum Gauges have been staples on American production lines for decades, whether digital or analog.

-

8900VG Digital Vacuum Gauge

$965.00 -

8901-T Gauge Tube / Transducer for 8900VG Vacuum Gauge

$177.00 -

8970 Gauge Tube / Transducer for 8990SM Vacuum Gauge

$139.00 -

8990-SM Analog Vacuum Gauge

$965.00 -

9001-T Gauge Tube / Transducer for APC – 2

$197.00 -

9020 Gauge Tube / Transducer for 9044SM Vacuum Gauge

$129.00 -

9044-SM Analog Vacuum Gauge

$965.00

Pressure Leak Testing

We offer some of the most reliable pressure leak detection and tracer gas charging stations available.

End of Line Testing

Airserco and its partners are proud to offer top-tier, fully-customizable safety and function test equipment. Our products are based upon a few modular systems that can be integrated and customized to provide as much or as little automatic functionality as required.

Tank Heaters & Controls

Keep your refrigerant pressure where it needs to be with Airserco refrigerant cylinder heating systems sized to your application. Pressure switches control the heater to ensure constant pressure is maintained while insulating blankets prevent heat loss.

-

4054 Manifold & Controller

$940.00 -

4054 Refrigerant Cylinder Heating Element Only

$517.00 -

4054 Refrigerant Cylinder Insulating Jacket

$445.00 -

4054M Complete Refrigerant Cylinder Heater Assembly

$1,880.00 -

5054 Complete Refrigerant Cylinder Heater Assembly

$2,800.00 -

5054 Manifold & Controller

$998.00 -

5054 Refrigerant Cylinder Insulating Jacket

$875.00 -

5054M Refrigerant Cylinder Heating Element Only

$965.00

Vacuum System Accessory Products

Our accessories include a range of essential tools designed for the refrigeration industry. They are built for precision and durability, intended to support and enhance standard refrigeration processes. Each product is selected to provide consistent and reliable performance for your refrigeration needs.

Request a Quote

We pride ourselves on accessibility and responsiveness. Please contact us with pricing information, or with any questions or comments you may have. Use the form below, or feel free to e-mail us at staycool@airserco.com or call

Reviews

There are no reviews yet.