A2L Refrigerant Charging System

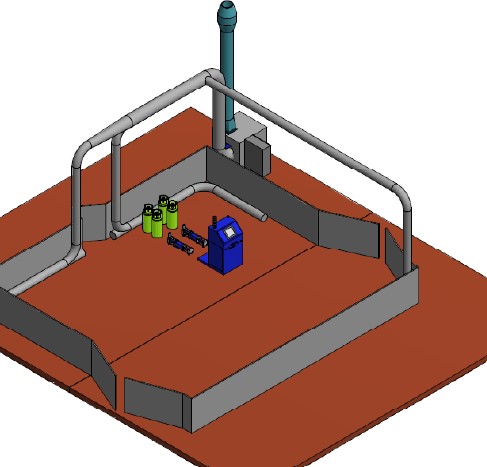

Airserco offers custom built A2L refrigerant charging areas that include a number of safety features to make your charging area comply with your facility’s specific location regulations.

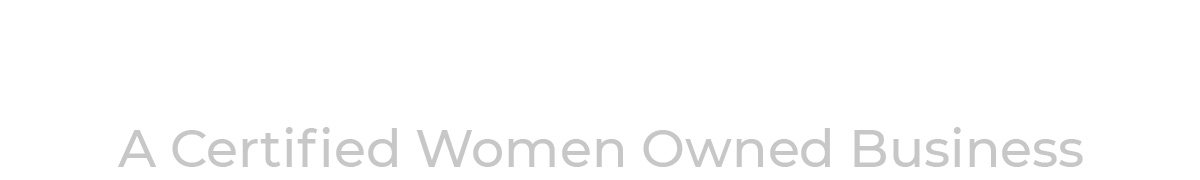

Airserco provides custom-designed A2L refrigerant charging systems for HVAC manufacturing plants transitioning to low-GWP refrigerants. Our turnkey installations include EPA-compliant charging stations that safely handle R454B, R32, R1234yf, R1234ze, and all A2L refrigerants with intrinsically safe components including spark-free motors, sealed electrical systems, and integrated leak detection.

With over 90 years serving the HVAC industry, Airserco specializes in A2L charging area design and installation including ventilation systems, safety equipment integration, and operator training. Our ASHRAE 15-compliant installations ensure safe handling of mildly flammable refrigerants while maximizing production efficiency and minimizing refrigerant losses. (Read more on navigating the shift to A2Ls.)

Available configurations include single or multi-station setups, automated tank changeover systems, refrigerant transfer pumps, and seamless integration with existing production lines. All installations meet UL safety standards and local building codes for A2L equipment handling.

Available A2L Charging Area Safety Components

- Charging Machines that are built for A1, A2L, and A3 Refrigerants. With optional integration of Pressure Testing, Tracer Gas Injection, Evacuation, Rise/Decay Testing, and PAG oil Injection.

- Medusa Safety Controllers - To monitor the Charging Environment and maintain a safe environment.

- Infrared Refrigerant Leak Sensors - To monitor the area for possible refrigerant leaks.

- Refrigerant Transfer Pumps

- Refrigerant Tank Change Systems

- Ventilation Extraction Systems

- Tank Isolation Valves

- Etc.

Microprocessor or smart OS (optional) controlled

Charging speed: up to 25 g/s for HC/HFO refrigerants and up

Charging capacity: according to local limitations

High charging accuracy

Built-in vacuum pump (20,5 m³/h)

Available with integrated Refrigerant transfer Pump

Interactive Color Touchscreen

Data Collection Application over TCP/IP protocol

Up to 1000 programmable work cycles Microprocessor-controlled

Built-in according to the European Machinery Directive, Safety standards for Potential Dangerous Areas

Works with A1, A2L, and A3 refrigerants including:

Class A1 – Non Flammable

- R134A

- R410A

- R-407C

- R-22

Class A2L – Mildly Flammable

- R454B

- R1234yf

- R1234ze

- R32

Class A3 – Highly Flammable

- R290 (propane)

- R600 (butane)

- R-600A (isobutane)

EPA-Compliant A2L Refrigerant Charging Systems

Complete Turnkey Installation & Regulatory Compliance

Expert Installation by Factory-Trained Technicians

We provide complete A2L refrigerant charging system installation for R454B, R32, and R1234yf applications (and more mildly flammable refrigerants). Our installations include safety barrier construction, ventilation extraction systems, infrared refrigerant leak sensors, and Medusa safety controllers. Each charging station handles A2L, and A3 refrigerants with charging speeds up to 25g/s. We research your specific local regulations and building codes to ensure your facility meets both federal EPA requirements and location-specific compliance.

With over 90 years serving the HVAC industry, Airserco specializes in A2L charging area design and installation. Our ASHRAE 15-compliant installations include ventilation systems, safety equipment integration, and operator training. We work with your team to integrate the new equipment with your existing production lines while maintaining your manufacturing schedule.

iRockall HC Technical Specifications

EPA-Compliant A2L Charging System for Production Environments

Performance

System & Safety

Physical

Connections

All systems customizable for specific production requirements

Request a Quote

We pride ourselves on accessibility and responsiveness. Please contact us with pricing information, or with any questions or comments you may have. Use the form below, or feel free to e-mail us at staycool@airserco.com or call

FAQs

Q: What refrigerants are supported by Airserco’s A2L charging systems?

A: Our systems are designed for all A2L refrigerants, including R-32, R-454B, R-1234yf, R-1234ze, and more. They can also be configured for A3 refrigerants.

Q: Do Airserco’s A2L systems meet EPA and ASHRAE safety standards?

A: Yes. All installations are ASHRAE 15-compliant and include EPA-compliant charging stations, spark-free motors, sealed electrical systems, and integrated leak detection.

Q: How fast can the A2L system charge refrigerants?

A: Depending on configuration, our systems can charge up to 25 g/s for A2L and A3 refrigerants with high accuracy and built-in safety controls.

Q: Does Airserco provide installation and training?

A: Yes – our factory-trained technicians handle full installation and provide operator training to ensure compliance and safety.