Automotive manufacturing is undergoing a fundamental shift in refrigerant technology. As OEMs transition vehicle thermal management systems from legacy R-134a to next-generation options, R290 (propane) has emerged as a compelling choice for manufacturers prioritizing sustainability, efficiency, and long-term regulatory compliance. This guide provides automotive manufacturing engineers with the technical specifications, safety requirements, and equipment considerations needed to implement R290 refrigerant charging systems on production lines.

Why Automotive Manufacturers Are Adopting R290

R290 refrigerant (propane) is classified as an A3 refrigerant under ASHRAE Standard 34, meaning it has low toxicity but high flammability. Despite the classification requiring stricter production line safety, R290 offers significant advantages that are driving adoption in automotive applications, particularly in EV battery thermal management and commercial transport:

Ultra-Low Global Warming Potential (GWP): R290 has a GWP of just 3, compared to 1,430 for R-134a and 4 for R-1234yf. For manufacturers facing increasingly stringent environmental regulations (such as PFAS restrictions that may impact HFOs), this represents a future-proof compliance advantage.

Superior Thermodynamic Efficiency: R290 delivers 10-15% better energy efficiency than R-134a in AC applications. In electric vehicles where every watt matters for range, this efficiency gain in the heat pump and battery cooling loops translates directly to extended driving distance.

Cost Stability: Unlike synthetic refrigerants subject to patent licensing and supply chain constraints, R290 is a commodity hydrocarbon with stable, predictable pricing. This reduces long-term operational costs and supply risk.

Lower Charge Quantities: Automotive R290 systems typically require 40-50% less refrigerant by weight than equivalent R-134a systems due to propane’s higher volumetric capacity. A typical vehicle AC system may use only 150-200g of R290 versus 400-600g of R-134a.

R290 Technical Properties for Manufacturing Engineers

Understanding R290’s physical and safety properties is essential for designing compliant charging systems. The following specifications directly impact equipment selection, facility design, and operating procedures.

R290 Refrigerant Properties

| Property | Value |

|---|---|

| Chemical Name | Propane |

| Chemical Formula | C₃H₈ |

| Molecular Weight | 44.1 g/mol |

| ASHRAE Safety Classification | A3 (Low Toxicity, High Flammability) |

| Global Warming Potential (GWP) | 3 |

| Ozone Depletion Potential (ODP) | 0 |

| Boiling Point (at 1 atm) | -42.1°C (-43.8°F) |

| Critical Temperature | 96.7°C (206.1°F) |

| Critical Pressure | 42.5 bar (616.3 psi) |

| Vapor Pressure at 25°C | 9.5 bar (137.8 psi) |

R290 Flammability Parameters

These parameters drive the safety system requirements for any R290 charging installation. The narrow range between the LFL and UFL requires precise detection equipment.

| Parameter | Value | Implication for Facility Design |

|---|---|---|

| Lower Flammability Limit (LFL) | 2.1% by volume | Gas detection must alarm well below this threshold (typically 15-20% of LFL) |

| Upper Flammability Limit (UFL) | 9.5% by volume | Defines the combustible range |

| Minimum Ignition Energy (MIE) | 0.25 mJ | Extremely low; requires strict ignition source control and ATEX Zone 2 compliance |

| Auto-Ignition Temperature | 470°C (878°F) | Hot work restrictions apply |

| Burning Velocity | 46 cm/s | Higher than A2L refrigerants; full containment recommended |

| Vapor Density (relative to air) | 1.52 | Heavier than air; floor-level extraction required |

The extremely low minimum ignition energy of R290 (0.25 mJ) is a critical design consideration. For context, a static discharge from a person can exceed 10,000 mJ. This means R290 charging areas require comprehensive electrostatic discharge (ESD) controls, including grounding systems, conductive flooring, and personnel grounding protocols.

R290 vs R-1234yf: Which Refrigerant for Your Production Line?

Automotive manufacturers currently have two primary low-GWP options: R290 (propane, A3) and R-1234yf (HFO, A2L). Understanding the tradeoffs helps in equipment planning and facility investment decisions.

| Factor | R290 (Propane) | R-1234yf |

|---|---|---|

| ASHRAE Classification | A3 (High Flammability) | A2L (Mild Flammability) |

| GWP | 3 | 4 |

| Refrigerant Cost | $3-5/kg | $40-80/kg |

| Typical Charge (Automotive) | 150-200g | 350-500g |

| Charging Equipment | Full containment required | Partial containment acceptable |

| Energy Efficiency | Excellent (10-15% better than R-134a) | Good (similar to R-134a) |

| Regulatory Status | Permitted with safety controls | Widely adopted standard |

| Patent/Licensing | None (commodity) | Licensed product |

When R290 makes sense: High-volume production where refrigerant cost savings compound significantly; EV manufacturers utilizing indirect cooling loops; companies with existing hydrocarbon handling experience; facilities willing to invest in full containment infrastructure.

When R-1234yf may be preferable: Lower production volumes where containment infrastructure ROI is longer; facilities with existing A2L equipment; markets where R-1234yf is the established OEM standard.

Many automotive manufacturers are planning dual-capability lines that can handle both refrigerants, providing flexibility as market demands evolve. Airserco’s iRockall HC charging systems are designed with this versatility in mind, supporting both A2L and A3 refrigerants on a single platform.

Safety Requirements for R290 Charging Installations

A3 refrigerants like R290 require full containment systems with comprehensive safety controls. This section outlines the key components automotive manufacturing engineers must specify when designing or procuring R290 charging infrastructure.

Full Containment Enclosure

Unlike A2L refrigerants that may use partial barriers, A3 systems require the charging station to be completely enclosed. Key specifications include:

- Non-flammable construction materials rated for the application

- Sealed entry/exit points with interlocked doors

- Floor-level sealing to prevent heavier-than-air gas migration

- Viewing windows (if required) made from appropriate safety glass

- Access panels for equipment maintenance with proper interlocks

Gas Detection and Monitoring System

Continuous monitoring is mandatory for R290 installations. The detection system must:

- Detect at 15% of LFL: First-stage alarm triggers at approximately 3,000 ppm (0.3% concentration)

- Escalate at 30% of LFL: Second-stage alarm with automatic equipment shutdown at approximately 6,000 ppm

- Multiple sensor placement: Sensors positioned at floor level throughout the enclosure (R290 is heavier than air)

- Redundant sensors: Critical safety systems should not rely on single-point detection

- Regular calibration: Using certified calibration gas to maintain accuracy

A system like the Medusa monitoring controller integrates all detection, ventilation, and safety interlock functions into a single command center, simplifying compliance and operational management.

Ventilation and Extraction System

Proper ventilation is critical for maintaining safe operating conditions and managing any leaks:

- Floor-level extraction: Intake ducts positioned at floor level along the enclosure perimeter

- Continuous operation: Ventilation runs whenever the system is active

- Variable speed control: Flow rates increase automatically when elevated gas concentrations are detected

- External discharge: Exhaust vented safely outside the building

- Interlock with charging system: Charging cannot proceed unless ventilation is confirmed operational

Electrical Classification and Ignition Source Control

Given R290’s extremely low minimum ignition energy, all electrical equipment within the containment zone must be appropriately rated:

- ATEX/IECEx Zone 2 classification (or equivalent) as minimum

- Intrinsically safe instrumentation where practical

- ESD controls: Conductive flooring, personnel grounding, bonding of all metallic components

- Tool control: Non-sparking tools required for maintenance within the zone

- Hot work prohibition: No welding, grinding, or open flame within the charging area

R290 Refrigerant Charging Equipment Requirements

The charging station itself must be purpose-built for flammable refrigerant handling. Key specifications for automotive manufacturing applications include:

Charging Accuracy

Automotive AC systems are charge-sensitive. R290’s efficiency advantage depends on precise charge quantities:

- Accuracy requirement: ±1g or better for typical automotive charges

- Repeatability: Essential for high-volume production consistency

- Verification: Integrated leak testing and charge verification

Cycle Time Performance

Production line integration requires equipment that matches takt time requirements:

- Evacuation capability: Deep vacuum to 500 microns or better

- Charge delivery: High-speed charging for production efficiency

- Recovery: Integrated refrigerant recovery for line stoppages or rework

Safety Compliance

All equipment in contact with R290 must meet explosive atmosphere requirements:

- ATEX Directive compliance for equipment used in explosive atmospheres

- Hermetically sealed components where practical

- Emergency shutdown integration with facility safety systems

- Data logging for traceability and quality documentation

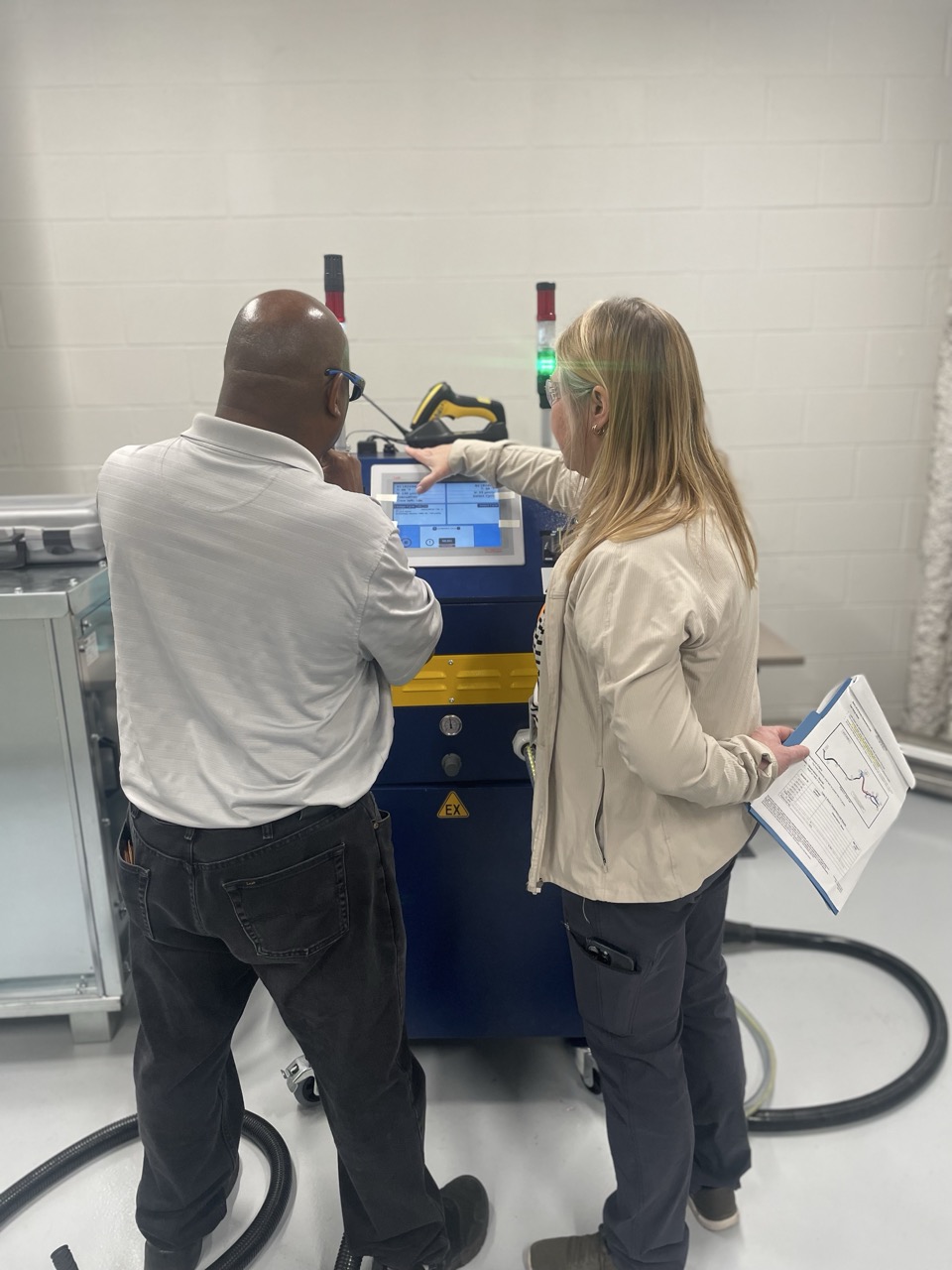

The iRockall HC Hydrocarbon Refrigerant Charging System is specifically engineered for R290 (and R600a) charging in production environments. It combines high-speed charging capability with ATEX-compliant design, making it suitable for automotive manufacturing lines where both throughput and safety are non-negotiable.

Regulatory Framework and Compliance

Automotive manufacturers must navigate multiple regulatory frameworks when implementing R290 charging systems:

EPA Regulations

The EPA’s AIM Act and SNAP program govern refrigerant use in the United States. While R290 use in passenger cabin cooling is subject to specific SNAP charge limits, it is increasingly favored for indirect systems and hermetically sealed loops. Manufacturers should verify current listings for their specific application and ensure charging operations meet EPA requirements for refrigerant handling.

ASHRAE Standards

ASHRAE Standard 15 (Safety Standard for Refrigeration Systems) and ASHRAE Standard 34 (Designation and Safety Classification of Refrigerants) provide the technical framework for safe R290 use. These standards inform charge limits, ventilation requirements, and equipment specifications.

OSHA Requirements

Workplace safety regulations require proper hazard communication, training, and engineering controls for flammable material handling. R290 installations must include appropriate signage, documented procedures, and emergency response planning.

State and Local Codes

Many jurisdictions have adopted or adapted building and fire codes that specifically address flammable refrigerant installations. California’s Title 24 and various state mechanical codes may impose additional requirements beyond federal standards.

Implementation Considerations for Manufacturing Engineers

When planning an R290 charging system installation, manufacturing engineers should address the following areas:

Facility Assessment

- Evaluate existing ventilation capacity and potential for upgrade

- Identify suitable location for full containment installation

- Assess electrical infrastructure for hazardous area classification requirements

- Review fire suppression and emergency response capabilities

- Determine refrigerant storage and handling logistics

Production Integration

- Calculate required cycle time and throughput

- Plan conveyor or vehicle positioning systems

- Design operator workflow for safety and efficiency

- Integrate with plant-wide MES and quality systems

- Establish maintenance access protocols

Training and Procedures

- Develop SOPs for normal operation, maintenance, and emergency response

- Train operators on flammable refrigerant hazards and safe handling

- Establish competency verification and refresher training schedules

- Document emergency procedures and evacuation routes

Ongoing Compliance

- Establish sensor calibration schedules using certified calibration gas

- Plan for regular safety system testing and verification

- Document all maintenance activities for regulatory compliance

- Schedule periodic third-party safety audits

Next Steps: Getting Started with R290 Charging

Implementing R290 refrigerant charging on an automotive production line requires careful planning, appropriate equipment, and comprehensive safety systems. The investment in proper infrastructure pays dividends through lower refrigerant costs, improved efficiency, and future-proof regulatory compliance.

Airserco has supported automotive and HVACR manufacturers with refrigerant charging solutions since 1933. Our engineering team provides consultation on system design, equipment selection, safety system integration, and turnkey installation for R290 and other flammable refrigerant applications.

Ready to evaluate R290 charging for your facility? Contact our engineering team to discuss your production requirements, review equipment options, and develop a compliance roadmap tailored to your operation.