The vacuum pump has been running fine for months. Then one morning, it won’t pull below 800 microns. The hoses check out. The connections are tight. The gauge is calibrated. The problem isn’t mechanical—it’s the oil.

Vacuum pump oil is easy to overlook in manufacturing environments where evacuation is already a bottleneck. But contaminated oil doesn’t fail dramatically. It degrades performance gradually, adding seconds to each cycle that compound across thousands of units. Those seconds become minutes. Minutes become hours of lost production capacity per week.

This guide covers the practical aspects of oil management that directly impact your evacuation performance: how contamination affects cycle times, what to look for during inspections, how to select the right oil for your application, and when to change it based on actual conditions rather than arbitrary schedules. We’ve previously covered evacuation best practices—this article focuses on the often-overlooked maintenance side of the equation.

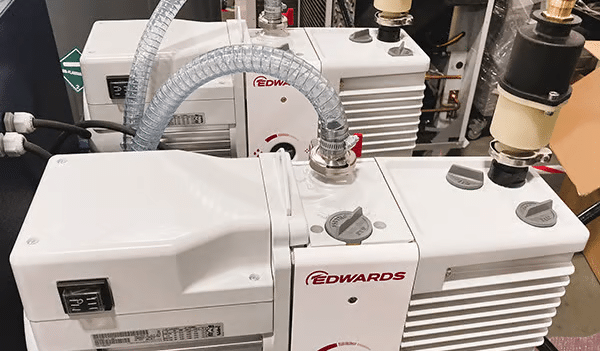

Free Printable Pump Inspection Log

One sheet per pump. Track oil color, evacuation times, and change history. Print it and clip it to the pump cart.

How Vacuum Pump Oil Actually Works

In rotary vane vacuum pumps, oil performs four distinct functions—and understanding each one explains why degraded oil impacts evacuation performance before the pump shows obvious signs of failure.

Sealing: Oil creates the seal between rotating vanes and the stator wall. This seal is what allows the pump to generate vacuum in the first place. When oil viscosity drops outside the designed range, this seal degrades and ultimate vacuum suffers—often before any other symptom appears.

Lubrication: The oil reduces friction between vanes and cylinder walls. Degraded oil means increased wear, which shortens pump life. But in the short term, increased friction also means higher operating temperatures and reduced efficiency.

Heat Dissipation: Oil carries heat away from compression zones. Contaminated oil has reduced thermal capacity, which leads to higher operating temperatures. This creates a feedback loop: higher temperatures accelerate oil degradation, which further reduces thermal capacity.

Contaminant Capture: This is the critical function for HVAC/R applications. The oil traps moisture, refrigerant traces, and particulates pulled from circuits during evacuation. The oil is doing its job when it captures these contaminants—but that same process is what degrades it.

Unlike laboratory applications where pumps may run clean for years, HVAC/R production lines expose vacuum pumps to significant moisture loading from every circuit evacuated. According to Leybold’s maintenance documentation, water circulating with pump oil reduces vacuum capability because water boils readily under vacuum on the inlet side of the pump. This is why production environments require more aggressive oil monitoring than the manufacturer’s baseline recommendations.

Identifying Oil Contamination

Visual Inspection: What Your Sight Glass Is Telling You

The most practical way to assess oil condition is visual inspection through the sight glass after the pump has been stopped for a few minutes. The following table summarizes what different oil appearances indicate:

| Oil Appearance | Condition | Action Required |

|---|---|---|

| Clear, pale gold | Good | Continue monitoring |

| Amber / light brown | Normal aging | Monitor more frequently |

| Dark brown / black | Particulate contamination or carbonization | Change immediately |

| Milky white / cloudy | Water contamination | Change immediately; check for system leaks |

| Frothy | Air entrainment or severe water contamination | Change immediately; investigate cause |

If oil appears milky and has been changed recently, you may be able to recover it by running the pump at full vacuum overnight with the gas ballast open. If the oil returns to a clear gold color by morning, it’s serviceable. If it remains cloudy, change it.

Beyond Visual Inspection

Viscosity changes: Oil that’s too thin won’t seal properly; oil that’s too thick impedes vane movement. Manufacturers specify viscosity ranges for a reason—degraded oil falls outside these parameters, even when color appears acceptable.

Odor indicators: A burnt smell indicates the pump has been running too hot, likely due to insufficient oil or overloading. Chemical odors suggest refrigerant contamination, which may require more frequent oil changes depending on the refrigerant type.

Performance degradation: If the pump struggles to reach target vacuum despite proper hose sizing and tight connections, suspect oil condition first. This is often the cheapest and fastest thing to fix—and frequently the actual problem.

Establish a weekly visual inspection protocol. It takes 30 seconds per pump. Log observations in a simple spreadsheet or maintenance system. This creates a history that helps predict when oil changes are actually needed versus following arbitrary calendar schedules. Accurate vacuum measurement—whether analog or digital—is essential for detecting the subtle performance degradation that precedes pump failure.

Oil Selection for HVAC/R Manufacturing

Mineral vs. Synthetic

Despite what some suppliers suggest, synthetic oils don’t automatically mean longer change intervals in HVAC/R manufacturing. The reasoning is straightforward: vacuum pumps actively ingest contamination. The oil chemistry matters less than how quickly contaminants accumulate.

As VPR USA (a member of the American Vacuum Society) notes in their maintenance guidance: using synthetic oil to extend the oil change interval is not recommended for vacuum pumps. While synthetic oils can be beneficial in compressors and gearboxes, those applications don’t suck in contamination to anywhere near the extent a vacuum pump does. It’s better to use a moderate-cost oil and change it frequently than to use an expensive synthetic and let contaminants build up.

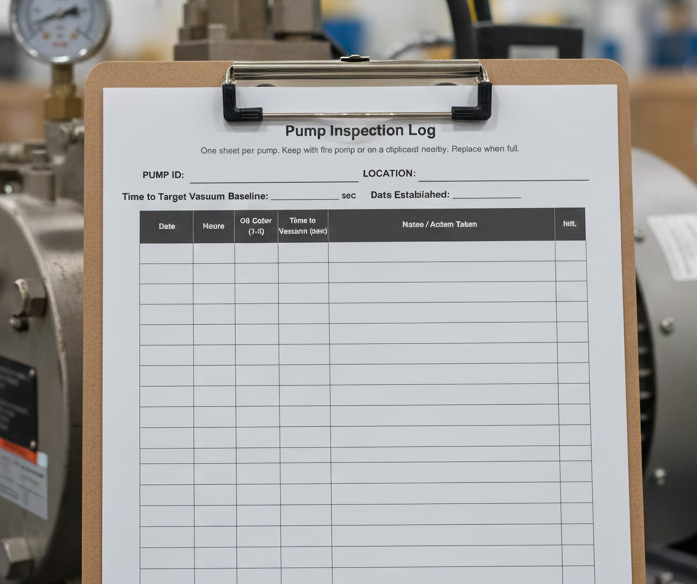

Edwards Ultragrade 19 Specifications

Ultragrade 19 is a hydrotreated mineral oil specifically formulated for rotary vane vacuum pumps in demanding applications. The hydrotreating process eliminates nitrogen, sulfur, oxygen, and aromatic hydrocarbons, leaving a base stock essentially free of impurities. Key specifications:

| Property | Value |

|---|---|

| Vapor Pressure at 20°C | 1 × 10⁻⁸ mbar |

| Vapor Pressure at 100°C | 1 × 10⁻³ mbar |

| Molecular Weight | 420 |

| Specific Gravity at 15°C | 0.86 |

Why these specifications matter for production:

- Low vapor pressure = better ultimate vacuum achievable

- Thermal stability = consistent performance during continuous operation

- Anti-oxidant additives = longer effective life between changes

Ultragrade 19 is compatible with Edwards RV3, RV5, RV8, RV12, E2M18, and E2M28 pumps, as well as Alcatel Adixen, Busch R5, Leybold Trivac, and Pfeiffer DUO Line pumps. Always verify compatibility before switching oil brands—the wrong viscosity or additive package can damage seals or reduce performance.

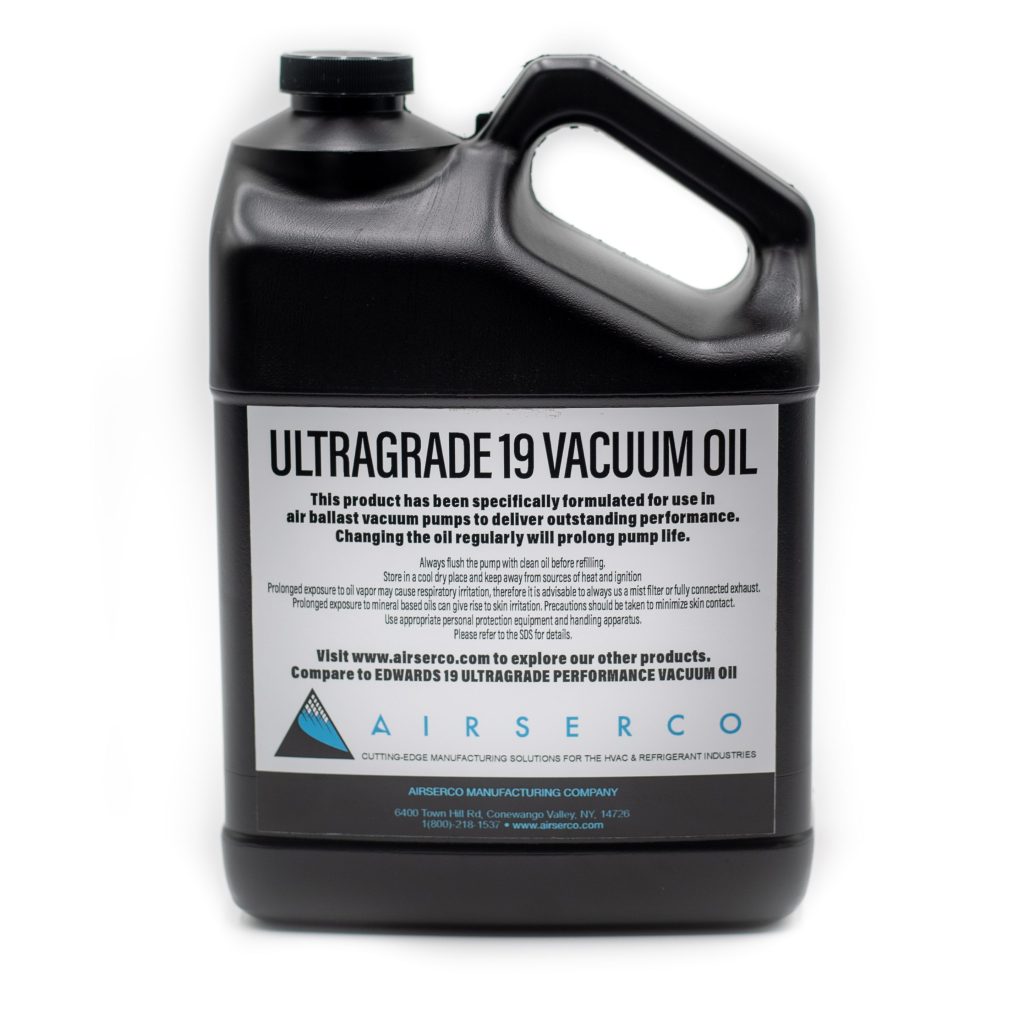

Airserco stocks Ultragrade Performance PURE 19 in gallon containers, formulated specifically for the high-demand cycling typical of HVAC/R production lines.

Change Intervals: Why Calendar-Based Schedules Miss the Point

The Problem with Fixed Intervals

“Change the oil every three months.” “Change it every 500 hours.” These recommendations ignore the variable that actually matters: contamination rate.

A pump evacuating 200 residential units per day accumulates contamination far faster than one evacuating 20 commercial units. A pump processing warranty returns with unknown moisture exposure needs different maintenance than one handling units straight from a dry production process. Fixed intervals either waste oil (changing too early) or risk damage (changing too late).

Becker Pumps, Leybold, and other manufacturers acknowledge that change intervals depend on pump type, operating conditions, temperature, contaminants, humidity, and application demands. The 500-1,000 hour recommendation is a baseline, not a rule.

A Condition-Based Approach for Manufacturing

Instead of guessing, implement condition-based monitoring:

- Baseline establishment: Immediately after an oil change, document oil color and measure time to reach target vacuum (e.g., 500 microns). This is your performance baseline.

- Weekly monitoring: Visual inspection plus performance check. Log results.

- Threshold triggers—change oil when:

- Oil reaches shade 4+ on color scale

- Time to target vacuum increases >15% from baseline

- Any milky or cloudy appearance

- Maximum interval backstop: Even if oil looks acceptable, don’t exceed manufacturer’s maximum interval—typically 500-1,000 hours for continuous operation.

Production-Specific Considerations

High moisture loading: If you’re processing units with suspected moisture contamination (warranty returns, units stored in humid conditions, units with manufacturing defects), consider changing oil after that batch rather than waiting for visual degradation.

Refrigerant exposure: Different refrigerants have different effects on pump oil. A2L refrigerants don’t inherently degrade oil faster, but the solvents or processing chemicals used with them might. Monitor more closely when introducing new refrigerant types to production.

Ambient conditions: High humidity environments accelerate water contamination of oil. If your facility isn’t climate-controlled, adjust monitoring frequency seasonally.

Cost perspective: A gallon of quality vacuum pump oil costs $110 – $150. A pump rebuild costs $500-2,000+. Downtime during an unplanned rebuild costs… you know your numbers better than we do. Err on the side of fresh oil.

Download the printable Pump Inspection Log to put this into practice.

Oil Change Procedure

An oil change should take 30-45 minutes per pump, including warm-up time. Rushing the process leads to incomplete drainage and contamination carryover into fresh oil.

Pre-Change Checklist

- Run pump for 30-60 minutes to reach operating temperature (warm oil drains completely)

- Prepare drain container, new oil, replacement drain plug gasket if needed

- Have absorbent materials ready for spills

- Confirm replacement oil quantity per pump model

Procedure Steps

- Shut down and position. Place drain container under oil drain plug. Ensure pump is level or slightly tilted toward drain.

- Drain completely. Remove drain plug. Allow 10-15 minutes for complete drainage. Warm oil drains faster and more completely than cold oil—this is why the warm-up step matters.

- Inspect drained oil. Note color, consistency, any particulates. This informs your contamination assessment and helps calibrate future inspection decisions.

- Optional flush. For heavily contaminated pumps, refill with fresh oil, run briefly without load, drain again. Some facilities use dedicated flushing oil for this step. This adds time but ensures contaminant carryover doesn’t immediately degrade the new charge.

- Refill. Add oil slowly to center of sight glass or fill line. Do not overfill—excess oil can blow past seals and enter the exhaust system.

- Run and verify. Start pump, run for 5 minutes, check that oil level remains stable and stays below top of sight glass.

- Document. Log date, pump ID, oil appearance at drain, and post-change performance baseline (time to reach target vacuum).

For multi-pump facilities, stagger oil changes to avoid taking all pumps offline simultaneously. If you’re running a Vacuum Pump Cart 5000 configuration, each cart can be serviced independently without disrupting other evacuation stations.

Extending Oil Life Without Compromising Performance

The real win isn’t finding cheaper oil—it’s keeping oil cleaner longer. Every contamination-reducing measure extends oil life and improves evacuation consistency.

- Inlet filtration. Inline filters or traps between the evacuation manifold and pump inlet capture particulates before they reach the oil. These add minimal flow restriction but significantly reduce contamination loading. Replace filters on a schedule or when pressure drop increases.

- Gas ballast operation. Most rotary vane pumps include a gas ballast valve. Opening it during evacuation of high-moisture systems allows water vapor to exhaust rather than condensing in the oil. The trade-off: slightly higher ultimate pressure (typically 0.5-1 mbar instead of 0.1 mbar). For most HVAC/R applications where 500-micron targets are standard, this trade-off is worthwhile when processing wet systems.

- Proper system preparation. Units arriving at evacuation stations with excess moisture—from storage, manufacturing processes, or improper refrigerant handling—contaminate oil faster. Address upstream processes where possible. It’s cheaper to prevent moisture entry than to deal with it at evacuation.

- Pump temperature management. Pumps running at proper operating temperature (typically 90-110°C / 194-230°F) keep oil above the point where water condenses. Cold pumps equal rapid oil contamination. If pumps are cycled frequently or sit idle between uses, allow adequate warm-up before processing wet systems.

- Post-shift procedures. If pumps will sit idle overnight, running them unloaded for 10-15 minutes before shutdown helps drive off accumulated moisture. This is especially important in humid environments or after processing systems with higher-than-normal moisture content.

Edwards documentation notes that Ultragrade anti-oxidants enable pumps to withstand high operating temperatures without oil degradation. Running pumps hot isn’t a problem—it’s actually beneficial for moisture management. Cold operation is the enemy.

The economics: Every contamination-reducing measure has a cost. But if inlet filtration lets you change oil monthly instead of weekly, the filter pays for itself within the first month. Calculate based on your actual oil consumption and labor costs.

Oil-Free Alternatives: When Dry Scroll Pumps Make Sense

Oil-free scroll pumps (Edwards nXDS, Leybold SCROLLVAC, Pfeiffer HiScroll, and similar) eliminate oil management entirely. No contamination concerns, no change intervals, no disposal requirements. They’re worth considering for certain applications.

Trade-offs for HVAC/R Manufacturing

- Ultimate vacuum: Many scroll pumps achieve 0.1 mbar or better—adequate for most HVAC/R evacuation targets.

- Upfront cost: Typically 2-3x equivalent rotary vane pump. The total cost of ownership calculation depends on your oil consumption, labor costs, and maintenance frequency.

- Pumping speed: Generally lower than comparable rotary vane pumps. For high-throughput applications, this may require larger pumps or parallel configurations.

- Maintenance: Tip seal replacement required, typically every 10,000-20,000 hours. Lower frequency than oil changes, but the procedure takes longer.

- Moisture handling: Some scroll pump models handle vapor better than others. Verify specifications for your application before purchasing.

For high-volume production with well-managed oil maintenance, rotary vane pumps remain cost-effective. Dry scroll pumps excel in applications where oil contamination is unacceptable, where maintenance labor is scarce, or where disposal regulations make oil management burdensome.

The right pump depends on your specific production requirements—there’s no universal answer.

Conclusion

Vacuum pump oil isn’t the exciting part of evacuation optimization, but it directly impacts cycle times, pump longevity, and maintenance costs. The key points:

- Condition-based monitoring beats calendar-based changes

- Visual inspection takes 30 seconds; skipping it costs hours

- Quality oil pays for itself in extended pump life

- Upstream contamination reduction extends oil life more than expensive oil formulations

If your evacuation times have crept up and you’ve ruled out hose restrictions and connections, check your oil first. It’s the cheapest fix—and often the actual problem.

For comprehensive evacuation optimization, our Evacuation Tips guide covers system-level improvements that complement proper oil maintenance.

Download the printable Pump Inspection Log to put this into practice.