Table of Contents

For decades, Helium (He) has been the industry standard for pressure leak testing in HVACR manufacturing due to its inert nature and small atomic size. However, volatile helium market dynamics—often referred to as “*Helium Shortage 4.0″—have forced OEMs to evaluate alternatives.

*(The industry calls it “Helium Shortage 4.0“—the fourth supply crisis since 2006, triggered when simultaneous failures at U.S. and Russian facilities removed a third of global helium production and sent prices soaring.)

Hydrogen (H₂), specifically in non-flammable “Forming Gas” mixtures (5% H₂ / 95% N₂), offers a compelling OpEx reduction. This analysis compares the two tracer gases across three critical vectors: Sensitivity thresholds, Cycle Time (clearing rates), and Cost-per-test.

1. Sensitivity Thresholds: The Physics of Detection

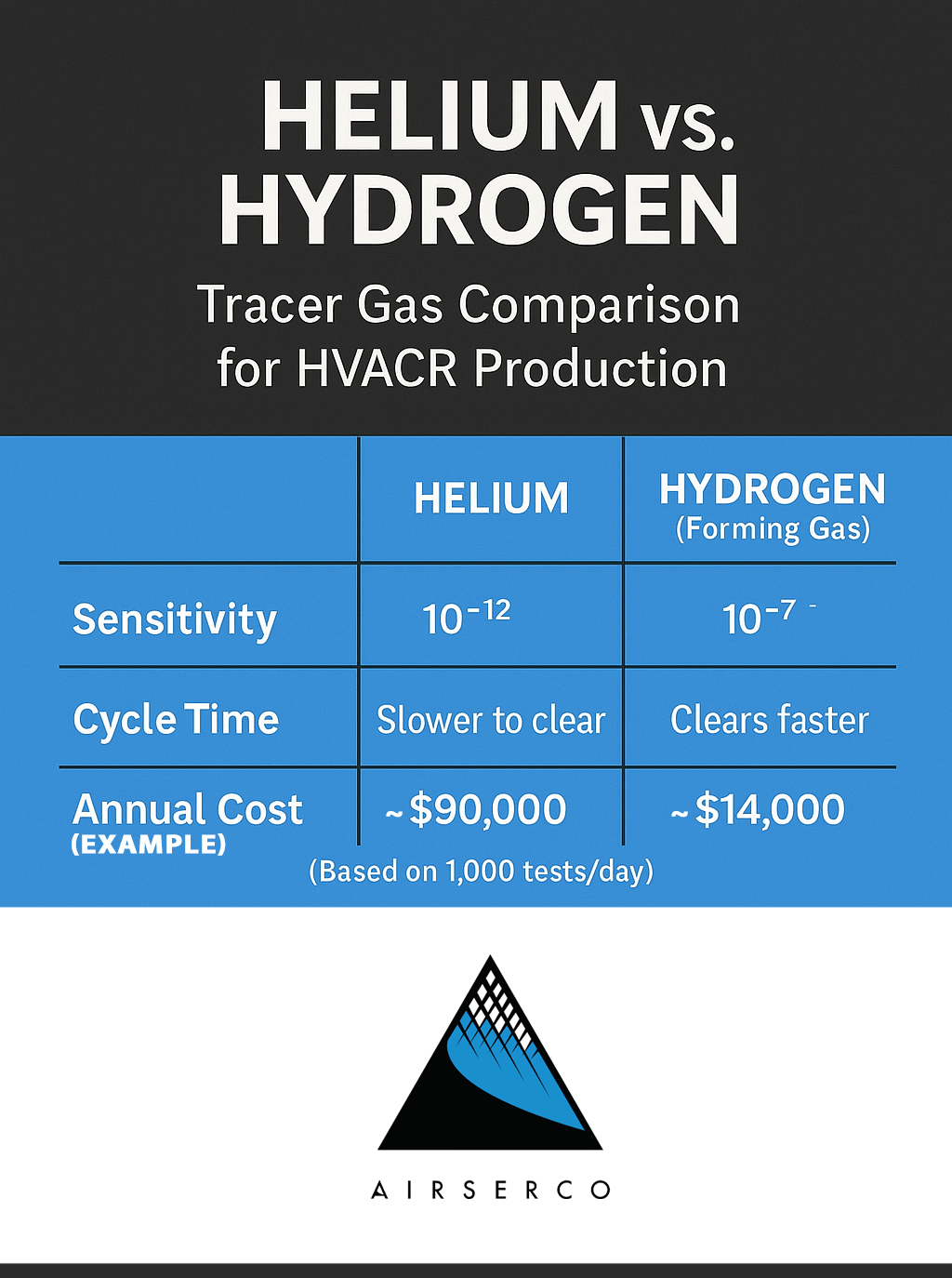

The primary hesitation in switching from Helium to Hydrogen is sensitivity. While Helium remains superior for ultra-high vacuum applications (semiconductors), Hydrogen is increasingly viable for HVACR production lines.

Comparative Detection Limits

| Parameter | Helium (He) Mass Spec | Hydrogen (5% H₂/95% N₂) |

|---|---|---|

| Minimum Detectable Leak | 1 × 10⁻¹² mbar·L/s | 5 × 10⁻⁷ mbar·L/s |

| Atomic Mass | 4 amu | 2 amu (Molecule) |

| Background Noise | Low (5 ppm in atmosphere) | Variable (Requires suppression) |

| HVAC Suitability | Excellent (All applications) | Excellent (Micro-channel, coils, braze joints) |

Engineering Note: For most HVACR production lines, the rejection threshold is typically between 0.1 to 2.0 oz/year (10⁻⁴ to 10⁻⁵ mbar·L/s). As shown above, Hydrogen (Forming Gas) detection capabilities (10⁻⁷) act well within the required sensitivity range for standard refrigerant containment, including A2L systems.

Source: NIST Physical Measurement Laboratory – Vacuum & Leak Standards

2. Cost Analysis: CapEx vs. OpEx

The economic argument for Hydrogen is driven by Operational Expenditure (OpEx). Helium is a finite resource derived from natural gas extraction, making its price highly inelastic. Hydrogen can be produced industrially, keeping costs stable.

The “Helium Economics” Problem

- Price Volatility: Helium prices have seen spikes of 100-250% during shortage events.

- Recovery Systems: To make Helium viable for high-speed lines, OEMs must install Helium Recovery Systems. These represent a significant Capital Expenditure (CapEx) and require regular maintenance of compressors and membranes.

The Hydrogen Advantage

- Gas Cost: A 5% H₂/95% N₂ mixture is typically 75-90% cheaper per cubic foot than pure Helium.

- No Recovery Needed: Because the gas is cheap and environmentally benign (venting Nitrogen and Hydrogen), recovery systems are unnecessary. This eliminates a major failure point in the production line.

Real-World Cost Comparison

| Production Volume | Annual Helium Cost | Annual Forming Gas Cost | Savings |

|---|---|---|---|

| 250 tests/day | ~$22,500 | ~$3,500 | $19,000/year |

| 500 tests/day | ~$45,000 | ~$7,000 | $38,000/year |

| 1,000 tests/day | ~$90,000 | ~$14,000 | $76,000/year |

Estimates based on 2024 industrial gas pricing. Actual costs vary by region and supplier contracts.

3. Safety & Compliance: Navigating Flammability

A common misconception among plant safety managers is that Hydrogen tracer gas introduces explosion risks. This is factually incorrect when using ISO-compliant mixtures.

- ISO 10156 Standard: A gas mixture containing less than 5.5% Hydrogen in Nitrogen is classified as non-flammable.

- Standard Mixture: The industry standard “Forming Gas” (also called P-5 or H-5) uses 5% H₂, providing a 0.5% safety buffer below the flammability limit.

- Green Manufacturing: Unlike Helium, which is a non-renewable resource, Hydrogen mixtures align better with sustainable manufacturing initiatives and ESG reporting requirements.

Source: Hydrogen Safety Standards; ISO 10156:2017

4. Production Line Cycle Time

For high-volume OEMs (e.g., producing 1,000+ units/day), cycle time is currency.

- Viscosity & Flow: Hydrogen has lower viscosity than Helium, allowing it to penetrate leaks slightly faster and “clear” from the test fixture more rapidly after a reject.

- The “Sticky” Problem: While Hydrogen clears the part quickly, it can be “sticky” in the background environment if the testing area has poor ventilation. Airserco mitigates this by designing custom ventilation hoods for the charging station.

The iAmiata portable tracer gas station is a bench station for mixing Helium + Nitrogen gases and realize tests leaks with rising vacuum, pressure decay and point to point micro leaks detections.

5. The A2L Connection: Why This Matters Now

If you’re reading this article, there’s a good chance you’re also navigating the EPA-mandated transition to A2L refrigerants. Many of our customers are discovering that retooling for A2L compliance is the perfect time to re-evaluate leak detection strategy.

Why combine these projects?

- Production line downtime is already planned for A2L equipment installation

- New A2L charging systems can be designed with hydrogen-compatible leak detection from day one

Contact us for a quote for our comprehensive A2L Charging System services. We offer installation and refrigerant charging stations.

Decision Framework: When to Switch

Stick with Helium if:

- You require leak testing below 1 × 10⁻⁹ mbar·L/s (e.g., ultra-high vacuum components)

- Your existing line already has a fully paid-for, high-efficiency Helium Recovery System with remaining useful life

Switch to Hydrogen if:

- Your target leak rate is in the standard HVAC range (10⁻⁵ range)

- You want to eliminate the maintenance overhead of Helium recovery compressors

- You need to stabilize OpEx against fluctuating gas commodities

- You’re retooling for A2L refrigerants anyway

Why OEMs Trust Airserco for This Transition

Airserco is a Certified Woman-Owned Business (WBENC) with over 90 years of experience engineering custom solutions for HVACR manufacturers. We’ve helped dozens of OEMs—from regional specialists to Fortune 500 manufacturers—successfully migrate from helium to hydrogen leak detection without sacrificing quality or throughput.

What sets us apart:

- Dual-gas capability: Our systems can run helium OR hydrogen, giving you flexibility as you transition

- Full A2L integration: Leak detection, refrigerant charging, and safety monitoring in one engineered system

- Production line expertise: We understand cycle time is money—our systems are designed for high-volume manufacturing

Take the Next Step

If you’re planning an A2L refrigerant transition, let’s discuss how to combine projects for maximum efficiency.

Schedule Engineering Consultation →

FAQs

Is hydrogen tracer gas flammable?

No, when used in standard “Forming Gas” mixtures (5% H₂ / 95% N₂). Per ISO 10156, gas mixtures containing less than 5.7% hydrogen in nitrogen are classified as non-flammable. The industry-standard 5% mixture provides a 0.7% safety buffer below the flammability threshold.

How much does forming gas cost compared to helium?

Forming gas (5% H₂/95% N₂) is typically 75-90% cheaper per cubic foot than pure helium. For a production line running 500 tests/day, this translates to approximately $38,000 in annual savings. Unlike helium, forming gas doesn’t require expensive recovery systems, further reducing total cost of ownership.

Can hydrogen leak detection match helium sensitivity for HVAC manufacturing?

Yes, for most HVAC applications. While helium detects leaks down to 10⁻¹² mbar·L/s, hydrogen forming gas reaches 10⁻⁷ mbar·L/s—well within the 10⁻⁴ to 10⁻⁵ mbar·L/s rejection threshold used for standard refrigerant containment, including A2L systems. Helium remains necessary only for ultra-high vacuum applications like semiconductors.

What is forming gas (P-5 gas)?

Forming gas, also called P-5 or H-5, is a non-flammable mixture of 5% hydrogen and 95% nitrogen used for industrial leak detection. It offers similar leak detection performance to helium at a fraction of the cost, without requiring gas recovery systems. The mixture meets ISO 10156 safety standards for non-flammable classification.

When should I switch from helium to hydrogen leak detection?

Consider switching if your target leak rate is in the standard HVAC range (10⁻⁵ mbar·L/s), you want to eliminate helium recovery system maintenance, or you need to stabilize operating costs against volatile helium pricing. The ideal time is during planned production line downtime—such as A2L refrigerant system installation—when retooling costs can be bundled.

Why combine hydrogen leak detection with A2L refrigerant upgrades?

Bundling these projects reduces total costs by 15-25%. Production line downtime is already planned for A2L equipment installation, new charging systems can integrate hydrogen-compatible leak detection from day one, and engineering resources can address both transitions simultaneously rather than disrupting production twice.